▲Provide by archy13

With the vigorous development of emerging industries such as 5G communications, artificial intelligence, and the Internet of Things, advanced processes based on FinFET technology will gradually be adopted by more and more chip companies. The use of advanced FinFET process technology can improve the integration of the chip, reduce the size of the chip, and at the same time can improve the computing efficiency of the chip and reduce the power consumption. At present, the industry's most advanced and mass production is the 5nm FinFET process technology. However, the advanced 5nm FinFET process technology makes the device's various parameters have approached its physical limits, such as extremely thin gate oxide layer, ultra-shallow source and drain junction depth, etc., all of which will make the chip more susceptible to electrostatic discharge ( ESD) event damage. System manufacturers will have more considerations when choosing ESD chips for system-level protection. In addition to requiring ultra-low capacitance products to reduce the loss and attenuation of high-speed signals, they also need lower turn-on voltage and clamping voltage (Vc), in order to ensure that when the external electrostatic pulse or surge pulse reaches the system, the ESD chip can start the response faster and provide lower clamping protection.

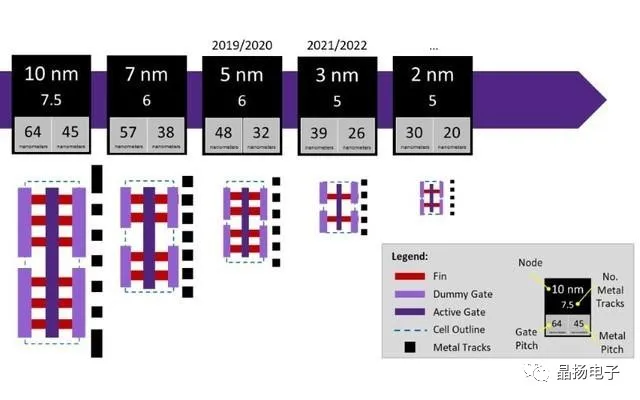

▲Intel process planning

▲Intel process planning

▲TSMC process planning

To satisfy the above mentioned new requirements, Jingyang Electronics is the first to launch an ESD product with lowest breakdown voltage, ultra-small capacitance and ultra-low clamping voltage - TT0214SP. It is designed to provide a more reliable ESD protection solution for the IC products with more advanced processes, especially for the 5nm FinFET technology.

▲TT0214SP产品特性

TT0214SP is a small package four-channel ESD array product of DFN2510-10L,the capacitance value is as low as 0.18pf, the breakdown voltage is as low as 3.5V (DC breakdown voltage), with snapback characteristics. It is the product with the lowest breakdown voltage among the ultra-small capacitance products with snapback characteristics in the industry, which can protect IC products with a working voltage lower than 2V from being damaged by surge (8/20us) at low voltages, and at the same time, it can respond faster when encountering electrostatic shocks, providing comprehensive protection. The TLP breakdown voltage of TT0214SP is controlled below 4V, which is the best level in the industry for this type of product and due to its snapback characteristics, the static Vc and surge Vc of this product are very low. When TLP=16A (8KV), Vc ≤5V, when Ipp=4A (8/20uS), Vc≤2.5V. The specific TLP and surge curves are as follows:

Other Low Capacitance Products:

The capacitance value of the above products is as low as 0.13pf, which is almost the lowest value in the industry. Under the TLP zapping current of 16A (or 8KV IEC gun test equally), their clamping voltage will be smaller than 7.5V, which can also provide an excellent ESD protection.

Power Supply Protection Products:

To provide the power supply protection of advanced technology ICs, it is recommended to use TT0301NA with DFN0603-2L package. Under the TLP zapping current of 16A (or 8KV IEC gun test equally), its clamping voltage will be smaller than 5.5V. What's more, it can sustain more than 10A (Ipp) under surge pulse (8/20us). All of these performance will make it to be a good choice for the power supply protection.